Flatbread for Foodservice: A Product R&D Case Study

Making the perfect flatbread match for a leading restaurant brand.

The Challenge:

Not Just Delicious, but Identical in Every Way.

When our customer, a top restaurant chain, approached us with a new private label flatbread project, they were in the process of rolling out an exciting new menu category featuring thaw and serve flatbread. The flatbreads forming the basis for the fun and share-able new menu items had already been developed and tested with another supplier.

Our customer was looking for a secondary partner to assure reliable supply leading up to a full nationwide menu launch, and they needed CraftMark to develop a perfect par-baked thaw and serve flatbread match that wasn’t just similar — it needed to look, taste, and perform exactly like their sample flatbreads. From the crispy crunch of the toasted edges, to a chewy bite, the team had a strict list of requirements to hit.

The CraftMark Bakery Solution:

Flatbread Expertise Required.

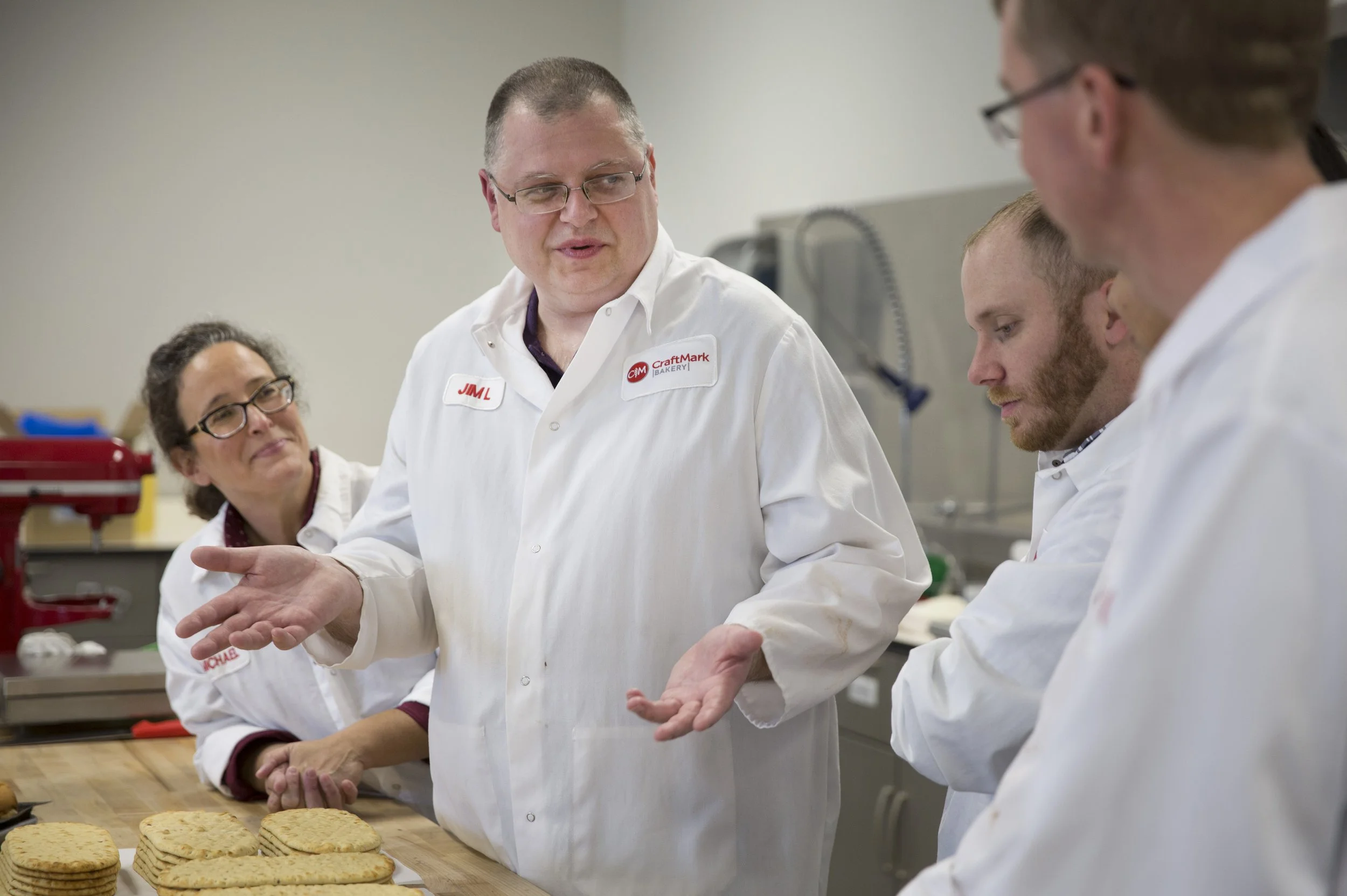

Provided with samples and specifications, our bakery Innovation and R&D team set to work on developing the perfect flatbread match. Luckily, the CraftMark Bakery team already included some of the most experienced flatbread experts in the industry, along with a proven private label flatbread manufacturing line which had been supporting other foodservice flatbread customers.

When it comes to private label flatbread manufacturing, it’s not just about formula, but also about the physical processes of time, temperature, hydration, aeration and handling as the dough makes it way through different stages of the production line and finally to baking. Every push and every fold has an effect, from introducing air that will eventually form bubbles during baking, to developing the gluten that yields a satisfying, chewy bite.

Our team was confident in their skill, and kicked off an organized development, iteration and testing process to match the customer’s thaw and serve flatbreads in every dimension, including flavor, texture, culinary performance and appearance.

Best Practices:

There’s No Substitute for the Production Line.

As CraftMark Bakery worked on matching the customer’s flatbreads, they had the pleasure to invite the customer to join them in the bakery. With flatbreads, it is about process as much as formula. You can’t match on the bench. You must go to the manufacturing line to produce product for customer review. Our customer visited CraftMark Bakery to oversee line trials and review the new flatbread products — hot off the line — for immediate feedback.

Take-Aways:

Continual Optimization in Flatbread Product Development Case Study: Making the Perfect Flatbread Match for a Leading Restaurant Brand.

Trust and confidence: these are the foundations of a strong partnership. We are pleased to say we have an excellent partnership with our foodservice customers. Our bakery is now their bakery. It is a pleasure to collaborate and manufacture their delicious restaurant flatbreads, and we take pride in the bakery R&D and operational expertise we bring to this story.

Your Flatbread R&D and Manufacturing Partner

The flatbread experts at CraftMark Bakery are standing by — contact our research and development experts to learn more about our process. Simply fill out the form below and we’ll be in touch!